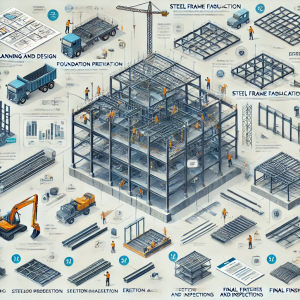

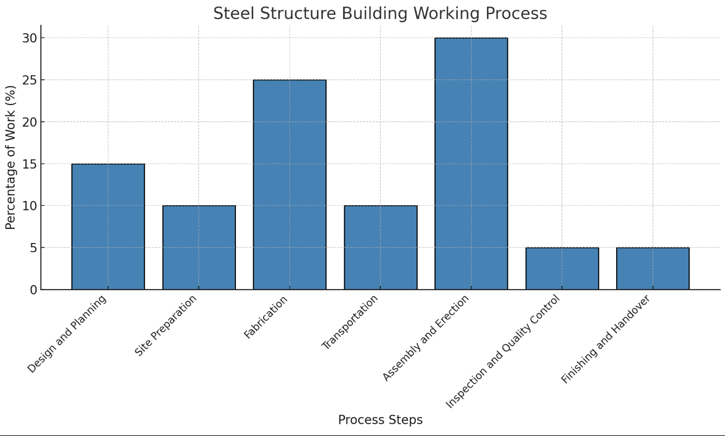

Steel structure building construction is a streamlined process involving various stages, from planning and execution to handover. Below is a detailed explanation of the process, tailored for Entrepreneur Power Engineering, a hypothetical company specializing in steel structure construction:

Post-Handover Services

Entrepreneur Power Engineering has become a trusted leader in the industries have successfully completed numerous projects in civil construction, architectural design, renewable energy, and infrastructure development, earning the satisfaction and trust of our clients.